Boston Whaler boats have a reputation for durability, safety, and long service life, but upholstery on these boats requires a very specific approach. If you are looking for professional work and want to get services specifically for this brand, you can visit this Boston Whaler upholstery service page. Whaler interiors are built differently, and mistakes in materials, patterns, or drainage become obvious fast. Upholstery here is not only about appearance. It directly affects comfort, water management, and long term value in real U.S. boating conditions.

What Makes Boston Whaler Upholstery Different

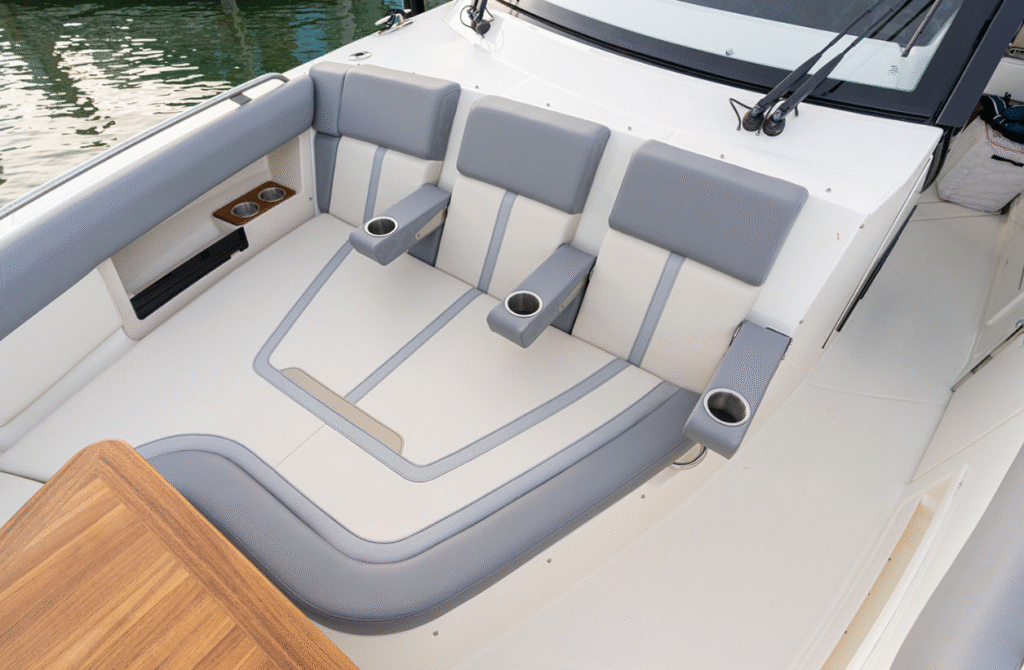

Boston Whaler builds interiors around function first. Seating is engineered to work with the hull, deck layout, and drainage system.

Boston Whaler upholstery typically features:

• Tight OEM patterns with minimal tolerance for error

• Molded fiberglass seat bases that demand precise fit

• Foam systems designed for frequent wet use

Generic upholstery solutions often fail because they are built for flat bases or universal seating frames, which Whalers rarely use.

Why OEM Patterns Matter on Boston Whaler Boats

Boston Whaler cushions are shaped to match exact contours of the deck and seating modules. Small deviations cause noticeable issues.

When patterns are off, owners may experience:

• Cushions sliding during operation

• Wrinkling that traps water

• Uneven pressure that accelerates foam breakdown

Helm seats, bow cushions, and leaning posts are especially sensitive. These areas see constant use and vibration, and even minor pattern errors become obvious over time.

Using correct Boston Whaler upholstery patterns helps maintain comfort and prevents early wear.

Foam Selection Is Not a Minor Detail

Foam is one of the most important components of Boston Whaler upholstery, yet it is often chosen incorrectly.

Whalers are commonly used offshore and in rough coastal conditions. Seating must absorb impact while drying quickly after exposure to water.

Proper foam characteristics include:

• Marine grade construction

• Resistance to water absorption

• Density that maintains shape under repeated load

Low quality foam compresses quickly and holds moisture. That leads to mildew smell, sagging cushions, and frequent replacement.

Sun and Salt Exposure in U.S. Conditions

Boston Whalers are popular in high exposure regions like Florida, the Gulf Coast, Southern California, and the Northeast.

Boston Whaler upholstery must handle:

• Constant UV exposure

• Salt buildup in seams

• Frequent wet and dry cycles

Marine vinyl with strong UV inhibitors performs far better than economy materials. Stitching also plays a critical role. UV resistant thread significantly extends seam life, especially on horizontal surfaces.

Ignoring these factors often results in faded panels and split seams within a few seasons.

Drainage Is a Core Design Principle

One of the most common upholstery mistakes on Boston Whalers is blocking drainage.

Whaler seating systems are designed to shed water quickly. Upholstery work must support that design, not fight it.

Key drainage considerations include:

• Breathable backing materials

• Correct alignment with factory drain paths

• Cushion construction that allows airflow

When water gets trapped under vinyl, damage begins internally. Foam degradation and mold often appear long before problems are visible from the outside.

Keeping the Original Boston Whaler Look

Many owners want updated interiors without losing the classic Whaler appearance. That balance is important.

Successful Boston Whaler upholstery updates usually follow a simple approach:

• Colors close to factory tones

• Clean panel layouts

• Minimal decorative stitching

Overdesigned interiors often look out of place on Whalers and can reduce resale appeal. Buyers expect a purposeful, clean look that matches the brand’s identity.

Repair or Full Replacement Decisions

Not every upholstery issue requires a complete replacement.

Repair is often appropriate when:

• Vinyl damage is localized

• Foam still holds shape

• Seams have failed but materials remain flexible

Full replacement becomes necessary when:

• Foam is waterlogged or collapsed

• Vinyl has hardened across multiple panels

• Cushions no longer align properly

Knowing when to repair versus replace helps owners avoid unnecessary expense while preserving factory intent.

Long Term Value of Proper Boston Whaler Upholstery

Boston Whalers retain value better than many boats in their class. Upholstery condition plays a major role in that value.

High quality Boston Whaler upholstery:

• Improves comfort underway

• Enhances safety by maintaining seating stability

• Preserves resale value

• Reduces long term maintenance costs

Poor workmanship is immediately noticeable to experienced buyers and marine surveyors.

Final Thoughts on Boston Whaler Upholstery

Boston Whaler upholstery is not standard marine upholstery. It requires attention to patterns, foam selection, drainage, and materials that match real U.S. boating conditions.

Owners who respect these nuances end up with interiors that age well, perform reliably, and reflect the same quality philosophy that made Boston Whaler famous in the first place.